Products Details:

Technical details of the FEMTA laser cleaning & welding systems as well as possible accessories for automation and fume extraction.

- FEMTA S-100

Parameters of the laser source:

- Wavelength 1064 nm (+/- 4 nm)

- Spectral width (FWHM): <5 nm (+/- 1 nm)

- Average output power: 100 W

- Power stability: 5

- Variable repetition rate: 25 - 230 kHz

- Switch-on time: <1min

Specifications of the laser gun:

- Scanner dimensions: 100 mm x 100 mm.

- Focus length (recommended): 100/160/210/254/330 mm

- Maximum scanning speed (at focus length): 10 m/s

- Recommended operating speed for highest accuracy: 9 m/s

- Laser gun dimensions and weight: <250 mm x <95 mm x <70 mm, 1.05 kg

- Variable scanning speed: 10-100 %.

System parameters:

- Fiber cable length: from 5 m (standard, recommended), up to 20 m.

- Cooling: Air cooled

- Operating humidity: 10% - 80%

- Operating temperature: from 0 to +40 °C

- Storage temperature: from -10 to +60 °C

- Power requirements: 230 V / AC 50-60 Hz, <6 A, single-phase plug

- Dimensions and weight: L-610 mm x D-520 mm x H-400 mm (with wheels 540mm), <52 kg.

System characteristics:

- Operating life: > 90 000 hours

- Warranty: 24 months

The package includes:

- Femta S-100

Laser cleaning system system maintenance and safety kit:

- IR radiation viewing card: (1 piece).

- Laser safety goggles: (2 pieces)

- Respirators: (2 pieces)

- Lens cleaning kit (1 piece)

- Technical documentation and manual.

Service and support:

- Training for system operators, 1 day (1-5 people).

- Warranty: 24 months.

- System integration support; after-sales service; damage repair.

- FEMTA S-200

Parameters of the laser source:

- Wavelength 1064 nm (+/- 4 nm)

- Spectral width (FWHM): <5 nm (+/- 1 nm)

- Average output power: 200 W

- Power stability: 5

- Variable repetition rate: 25 - 230 kHz

- Switch-on time: <1min

Specifications of the laser gun:

- Scanner dimensions: 100 mm x 100 mm.

- Focus length (recommended): 100/160/210/254/330 mm

- Maximum scanning speed (at focus length): 10 m/s

- Recommended operating speed for highest accuracy: 9 m/s

- Laser gun dimensions and weight: <250 mm x <95 mm x <70 mm, 1.05 kg

- Variable scanning speed: 10-100 %.

System parameters:

- Fiber cable length: from 5 m (standard, recommended), up to 20 m.

- Cooling: Air cooled

- Operating humidity: 10% - 80%

- Operating temperature: from 0 to +40 °C

- Storage temperature: from -10 to +60 °C

- Power requirements: 230 V / AC 50-60 Hz, <6 A, single-phase plug

- Dimensions and weight: L-610 mm x D-520 mm x H-400 mm (with wheels 540mm), <52 kg.

System characteristics:

- Operating life: > 90 000 hours

- Warranty: 24 months

The package includes:

- Femta S-200

Laser cleaning system system maintenance and safety kit:

- IR radiation viewing card: (1 piece).

- Laser safety goggles: (2 pieces)

- Respirators: (2 pieces)

- Lens cleaning kit (1 piece)

- Technical documentation and manual.

Service and support:

- Training for system operators, 1 day (1-5 people).

- Warranty: 24 months.

- System integration support; after-sales service; damage repair.

- FEMTA X-1A Laser welding system

Parameters of the laser source:

- Wavelength: 1080 nm (+/- 4 nm)

- Output: Continuous wave (CW) or pulsed (selectable)

- Output power: 1500 W

- Spectrum width (FWHM): <5 nm (+/- 1 nm)

- Power stability: 5%

- Start-up time: <1 min

Laser gun specifications:

- Weld line width: 0 - 4 mm

- Scanning speed (at focus length): 0 - 300 Hz

- Laser gun weight: 690 g

System parameters:

- Length of the fiber cable: 5 m

- Cooling of the laser source: air cooled

- Laser gun mirror cooling: welding gas (recommended: nitrogen, 99.99% purity)

- Welding gas requirements: pressure >80 kPa, flow rate 15 l/min.

- Welding wire diameter with automatic feeding: 0.8 - 1.6 mm

- Operating humidity: 10% - 80%

- Operating temperature: from 0 to +40 °C

- Storage temperature: from -10 to +60 °C

- Power requirements: 230 V / AC 50-60 Hz, < 30 A, single phase

- Dimensions and weight: L-276 mm x D-667 mm x H-542 mm, 39 kg.

System features:

- Operating life: > 50 000 hours

- Warranty: 24 months for laser welding system. 12 months for welding wire feeder machine. The warranty does not apply to consumable laser parts such as: Laser gun copper ends; protective lens.

Maximum welding depth:

- Stainless steel (SUS304): 4.5 mm.

- Carbon steel (Q235B): 4.5 mm

- Aluminum sheets (Al6061): 3 mm

- Galvanized steel sheets: 3.5 mm

- Brass: 3.5 mm

The package contains:

- Femta X-1 laser welder:

- Air-cooled laser source with laser gun (1 piece).

- 10 meter long grounding cable (1 piece)

- 10 meter long power supply cable (1 piece)

- Laser gun copper nozzles: 1, 3, A, B, flat (2 pieces of each type)

- Spare protective lens set (3 pieces)

- Automatic welding wire feeder (1 piece)

- Automatic welding wire fixing parts for laser gun (1 piece)

- Welding wire feeding nozzles for 0.8/1.0/1.2/1.6 mm welding wire (1 piece of each diameter)

- Laser protection parts:

- Certified laser safety goggles: (3 pcs.)

- Breathing masks (3 pieces)

- Earplugs (3 pieces)

- Laser maintenance kit:

- Lens cleaning kit (1 piece).

- Technical documentation and manual

Service and support:

- Training for system operators (1-5 people).

- Warranty: 24 months.

- System integration support; after-sales service; damage repair.

- FEMTA MA1-65 Laser welding system

Parameters of the laser source:

- Wavelength: 1080 nm (+/- 4 nm)

- Output: Continuous wave (CW) or pulsed (selectable)

- Output power: 2000 W

- Spectrum width (FWHM): <5 nm (+/- 1 nm)

- Power stability: 5%

- Start-up time: <1 min

Laser gun specifications:

- Weld line width: 0 - 4 mm

- Scanning speed (at focus length): 0 - 300 Hz

- Laser gun weight: 690 g

System parameters:

- Length of the fiber cable: 5 m

- Cooling of the laser source: air cooled

- Laser gun mirror cooling: welding gas (recommended: nitrogen, 99.99% purity)

- Welding gas requirements: pressure >80 kPa, flow rate 15 l/min.

- Welding wire diameter with automatic feeding: 0.8 - 1.6 mm

- Operating humidity: 10% - 80%

- Operating temperature: from 0 to +40 °C

- Storage temperature: from -10 to +60 °C

- Power requirements: 400 V / AC 50-60 Hz, < 22 A, three-phase

- Dimensions and weight: L-276 mm x D-667 mm x H-542 mm, 40 kg.

System characteristics:

- Operating life: > 50 000 hours

- Warranty: 24 months for laser welding system. 12 months for welding wire feeder machine. The warranty does not apply to consumable laser parts such as: Laser gun copper ends; protective lens.

Maximum welding depth:

- Stainless steel (SUS304): 6.5 mm.

- Carbon steel (Q235B): 6.5 mm

- Aluminum sheets (Al6061): 5.5 mm

- Galvanized steel sheets: 6.5 mm

- Brass: 4.5 mm

- Copper: 3 mm

The package contains:

- FEMTA MA-65 laser welder:

- Air-cooled laser source with laser gun (1 piece).

- 10 meter long grounding cable (1 piece)

- 10 meter long power supply cable (1 piece)

- Laser gun copper nozzles: 1, 3, A, B, flat (2 pieces of each type)

- Spare protective lens set (3 pieces)

- Automatic welding wire feeder (1 piece)

- Automatic welding wire fixing parts for laser gun (1 piece)

- Welding wire feeding nozzles for 0.8/1.0/1.2/1.6 mm welding wire (1 piece of each diameter)

- Laser protection parts:

- Certified laser safety goggles: (3 pcs.)

- Breathing masks (3 pieces)

- Earplugs (3 pieces)

- Laser maintenance kit:

- Lens cleaning kit (1 piece).

- Technical documentation and manual

Service and support:

- Training for system operators (1-5 people).

- Warranty: 24 months.

- System integration support; after-sales service; damage repair.

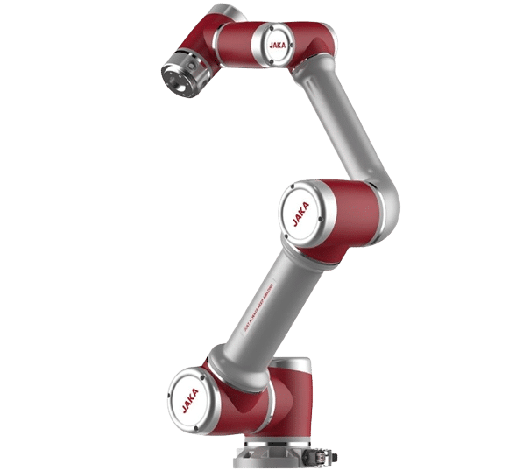

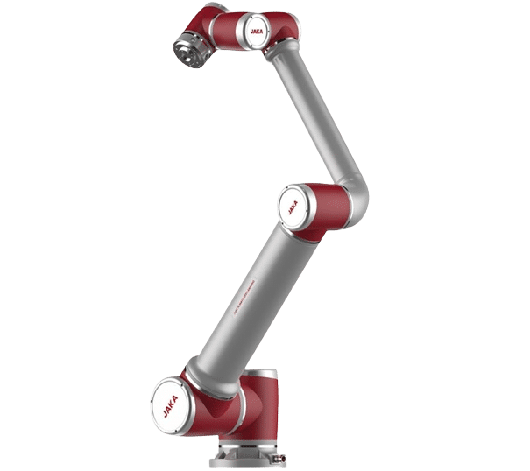

- Cooperation robots / cobots from JAKA

JAKA PRO 5

- Working radius: 954 mm

- Loading weight: 5 kg

JAKA PRO 12

- Working radius: 1327 mm

- Loading weight: 12 kg

JAKA PRO 16

- Working radius: 1713 mm

- Loading weight: 16 kg

Discover the future of industrial cleaning and laser welding with our groundbreaking combination of cooperative robots and laser systems.

Our cooperative robots are specifically designed for use in conjunction with laser cleaning systems and laser welding equipment. The precise control and flexibility of our robots takes the cleaning and welding of materials to a new level.

By integrating cooperative robots with laser cleaning systems, we provide an automated solution that enables efficient and thorough cleaning of a wide variety of surfaces. The robots work in perfect synchronization with the laser beams to precisely remove contaminants while maintaining the integrity of the materials. The flexibility of the robot arms means that even hard-to-reach areas can be reached, greatly expanding the range of applications.

In the field of laser welding, our collaborative robots enable precise alignment and movement of the laser beam to produce a high-quality and reliable weld. The robots support the welding processes by accurately positioning the materials and ensuring consistent speed and welding motion.

The combination of collaborative robots and laser equipment offers a number of benefits, including:

Increased productivity: automating cleaning and welding processes can speed up workflows and increase overall productivity.

Precision and quality: precise control of robots combined with laser beams enables high cleaning and welding quality and consistent results.

Flexibility and adaptability: our collaborative robots are versatile and can be adapted to different requirements and materials. They offer flexibility in performing cleaning and welding tasks.

Safety and collaboration: our robots are equipped with advanced safety features to ensure safe collaboration with human operators. This allows cleaning and welding processes to be performed efficiently and safely.

Experience the benefits of combining collaborative robots and laser equipment in industrial cleaning and laser welding.

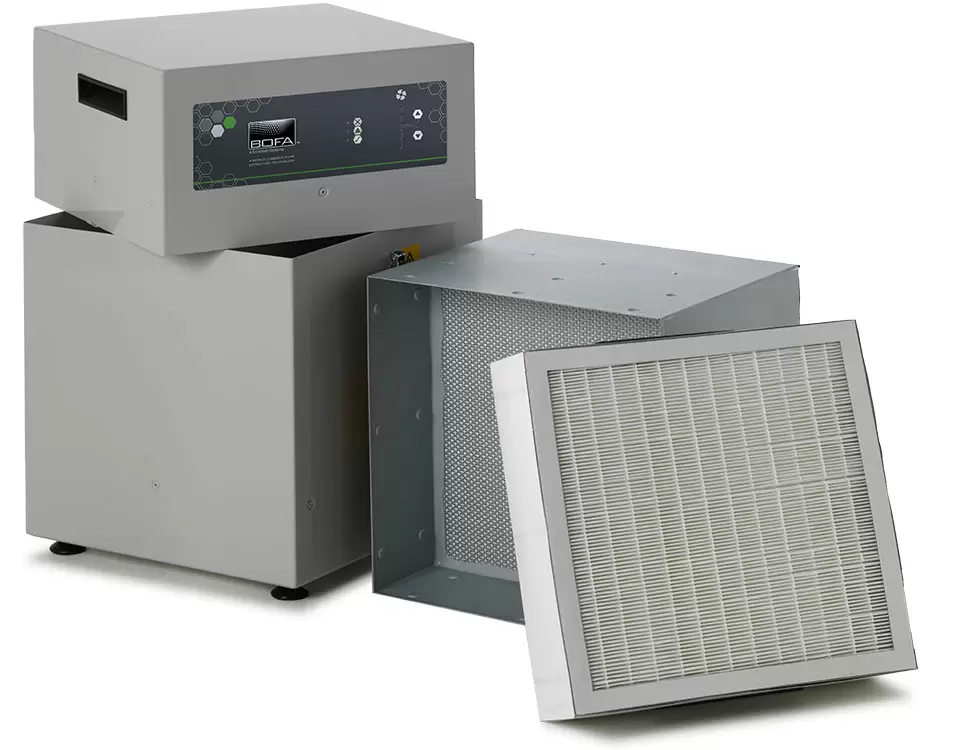

- Fume & Gas Extraction Systems from BOFA

Fume extractors play a critical role in these applications, as they are used to effectively remove harmful fumes, vapors and particles during laser welding and laser cleaning. Here are some reasons why fume extraction systems are essential:

Health protection: laser welding and laser cleaning produce fumes, vapors and particles that can be harmful to health. Fume extraction ensures that these pollutants are immediately extracted and removed from the work environment. This minimizes potential health risks to employees.

Clean working environment: The effective extraction of fumes and particles helps to keep the working environment clean. This is particularly important as contamination from smoke particles can impair visibility of the workpiece. A clear view ensures precise execution of welding and cleaning processes.

Machine protection: Smoke and particles can also affect laser welding systems and laser cleaning equipment. Fume extraction prevents the buildup of contaminants on the optics and components of the equipment. This increases the life of the machines and reduces maintenance.

Environmental protection: The separation of fumes and particles is also of great importance from an ecological point of view. By using fume extraction systems, companies help reduce emissions and the discharge of harmful substances into the environment.

We offer high-quality fume extraction systems that have been specially developed for laser welding systems and laser cleaning systems. Our extraction solutions are efficient, powerful and tailored to the requirements of your application. They ensure reliable removal of fumes and particles to create a safe and clean working environment.

Convince yourself of the efficiency, precision and versatility of FEMTA laser systems and contact us to discuss your individual requirements.